With the increasing installation and construction of photovoltaic power stations, the quality of PV power stations is particularly important, so the most important detection method for PV power stations - EL detection (internal defect detection) has gradually developed from random inspection to full inspection.

1.Early construction of PV power station - EL detection of incoming components

The EL detection of incoming PV modules is mainly to control the outgoing quality of PV modules , and whether the items are affected by the transportation ; If there are EL defects, we can communicate with the manufacturer in time to avoid the problem of unclear division of responsibility for quality problems of the power station.

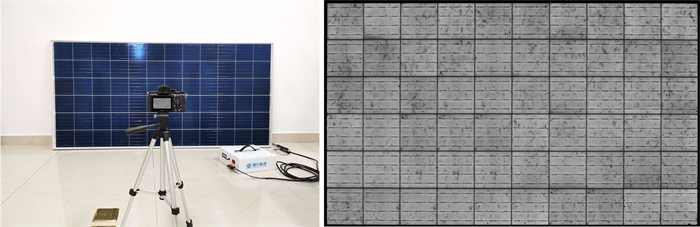

1.1 Indoor EL detection

If there are indoor conditions on the site, a closed room can be found as the test site. Before the test, the Windows and doors in the house need to be completely shielded to avoid the penetration of sunlight to affect the test effect (the indoor fluorescent lamp has no impact on the test).

During the test, each component is placed diagonally on a wall or other object and the component is EL tested using a portable EL detector.

1.2 Outdoor dark room EL detection (daytime detection)

Most power stations do not have indoor conditions, so portable dark room in portable EL detector can be used to quickly build a dark room on site for EL testing. With its windproof, waterproof and infrared resistant outer layer, which can effectively block the sunlight. During the test, each component is transported to the interior of the dark room and EL detection is performed by relying on the component support frame on both sides (such as dark room testing is not required for night testing).

2.In the construction of photovoltaic power station - EL detection of PV module mounted on the bracket

The EL inspection of PV module after installation is to control the installation quality of the construction team installing components. By comparing the EL pictures of incoming PV module with installed PV module, it is very easy to find whether defects occur during the installation of components. Effectively assign responsibility for component defects.

2.1 Night EL Detection with tripod (Night Detection)

The portable EL detector with The tripod can be applied to most photovoltaic power stations, and the EL image can be obtained by pointing the camera at the component under test and conducting a power test on the component .

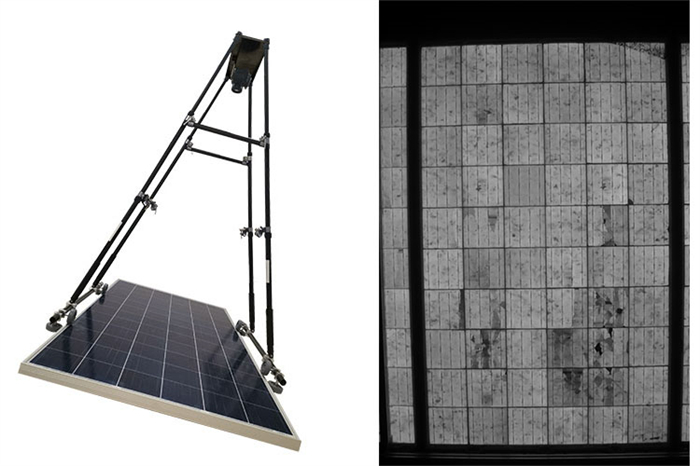

2.2 Dark room EL detection with stent (daytime detection)

If you want to perform EL inspection on the mount during the day, you can also package the test mount (the camera is fixed in the packaging material) and power test the component. As shown in the above picture, because the components on the support can not be completely sealed around and on the back, the test effect is not perfect under strong sunlight conditions; This type of test is extremely limited, and the tiled roof type power station is chosen as far as possible to effectively shield the bottom of the component, because of the fixed support module, the test efficiency is not good.

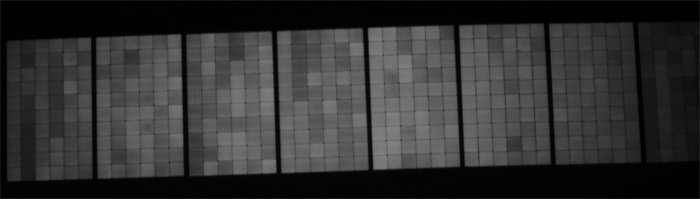

2.3 Daytime EL detection (Daytime detection)

Most photovoltaic people are very interested in the appearance of daytime EL test, and think that it can solve the pain points of traditional EL test, this device relies on indium gallium arsenic chip to short-wave infrared high sensitivity, high-frequency power current import for daytime EL imaging; However, it has not been adopted by the photovoltaic industry because of high prices, extremely low pixels, and poor image clarity. The daytime EL test still does not solve the traditional power-on test problem, and relying on the power supply to power up the components is the real bottleneck of EL testing. It is believed that with the progress of technology, the test industry will overcome this test bottleneck.

2.4 Custom sliding EL detection (night)

In the large-scale random inspection or full inspection of photovoltaic power stations, in order to improve the test efficiency, it is necessary to customize the exclusive power station EL test equipment; As shown in the figure above, the EL test camera is driven by the customized bracket to move quickly on the photovoltaic power station bracket. At the same time, with the high-power series power supply, the series power switch is carried out in the bus box or the inverter end.

3. After the completion of photovoltaic power station construction - EL detection in power station operation and maintenance

3.1 Handheld EL detection

In the late operation and maintenance of photovoltaic power stations, it is often only necessary to find the fault location, so for the need to quickly find the EL problem location, Zhisen technology has developed a handheld EL video tester, users can use the EL camera for real-time view, but also for video storage and retention, no need to shoot and wait, can quickly find the EL defect location.

3.2 Drone EL detection

For power stations with special terrain, such as water surface power stations and greenhouse power stations, which are relatively high and cannot be tested by personnel, EL detection technology of UAV can be used to carry out EL testing on such power stations. The EL video technology is also applied to carry out EL video test on photovoltaic power station, and the EL image can be extracted in the later stage.

Advantages of UAV detection: it is not limited by terrain conditions, can solve the basic EL test, and monitor the real quality of the power station; Disadvantages: 1. There are more testers, and testers are needed in every link, especially professional pilots. 2. The fast switching of the power supply is more difficult, the speed of the series power switching in the EL test of the drone directly affects the test rate, and the distance between the bus box or inverter is often far, each bus box is generally up to 16 string components, so how to quickly switch the power series still needs to be considered. 3. The test effect is not perfect, the EL test effect of UAV is still some gap when taking photos of normal EL test effect, and serious defects can be found, such as black core, debris, etc.; However, the display effect of subtle cracks is not good.

Aircraft endurance is currently about 20 minutes, according to the normal test rate tight enough to test 5 series of components need to land, if large-scale power station test, must be configured with multiple sets of aircraft batteries, and aircraft batteries are expensive. Summary: The above includes almost all types of EL test methods at present, I hope that with the progress of technology, EL test can be completed during the day and without powering the component, similar to thermal like test, so as to solve the tedious test work of photovoltaic people.

Welcome to visit us at exhibition

Wind and solar to produce 33% of global power by

Contact: Mirror Zhang

Phone: +86-13264588177

Tel: +86-13264588177

Email: mirror@big-eye-tech.com

Add: 3F, Building 2, No. 511, Xiaowan Road, Fengxian District, Shanghai

We chat